Understanding Metal Manufacturing in Edmonton

Edmonton, renowned for its robust industrial infrastructure, is home to numerous metal manufacturers delivering diverse services and products. The growing demand for precision-engineered metal components has positioned Edmonton as a hub for metal fabrication. This article delves into the intricacies of metal manufacturing, highlighting essential processes, services offered by manufacturers, and how to choose a reliable partner for your fabrication needs. With a focus on metal manufacturer edmonton, we explore themes relevant to both businesses and consumers looking to delve into custom metal solutions.

What is Metal Fabrication?

Metal fabrication refers to the process of building metal structures and components through cutting, bending, welding, and assembling. It encompasses a variety of techniques and practices that transform raw metal materials into finished products. In Edmonton, metal fabrication serves numerous industries, from construction and automotive to aerospace and electronic manufacturing, showcasing the versatility and critical role of metal manufacturers within the supply chain.

Key Processes Used by Metal Manufacturers

Metal manufacturers employ a range of processes to meet diverse needs, including:

- Laser Cutting: Utilizes high-powered lasers to cut materials with precision, offering intricate shapes and designs.

- Plasma Cutting: Involves using a plasma torch to cut through conductive metals, providing fast and efficient results.

- Welding: Joins two metal pieces by melting and fusing them, crucial for creating strong structural components.

- Bending: Alters the shape of metal sheets or parts, essential for producing various angles and forms.

- Finishing: Includes processes such as painting, coating, or polishing to protect against corrosion and enhance aesthetic appeal.

The Importance of Quality Standards

Quality standards are paramount in metal manufacturing. Certification to international standards such as ISO 9001 ensures that manufacturers consistently deliver products that meet customer expectations and regulatory requirements. This commitment to quality is vital for maintaining safety, function, and durability across various applications. In an industry where precision is essential, adherence to quality standards differentiates reputable manufacturers from the competition.

Services Offered by Metal Manufacturers in Edmonton

Edmonton’s metal manufacturers provide a wide array of services to cater to the diverse needs of their clients, enhancing the overall value proposition of their offerings.

Custom Metal Fabrication Explained

Custom metal fabrication is the creation of metal components tailored to specific client specifications. This process allows for flexibility in design and material choice, enabling companies to create unique products for their applications. Metal manufacturers in Edmonton can accommodate projects of various sizes, from small parts to large structural components, meeting strict timelines while ensuring high-quality outcomes.

Types of Metals Processed by Local Manufacturers

Edmonton’s metal manufacturers work with a range of metals, including:

- Steel: Noted for its strength and durability, steel is commonly used in construction, machinery, and automotive applications.

- Stainless Steel: Known for its corrosion resistance, this material is ideal for food processing, medical devices, and architecture.

- Aluminum: Lightweight yet strong, aluminum is perfect for industries requiring reduced weight without sacrificing strength, such as aerospace.

- Brass and Copper: These metals are often used in electrical applications due to their conductivity and resistance to corrosion.

Value-Added Services and Solutions

Beyond fabrication, Edmonton metal manufacturers often offer value-added services that enhance customer experience and product utility. These may include:

- Design Assistance: Collaborating with clients during the initial design phase to optimize designs for manufacturability.

- Assembly Services: Providing end-to-end solutions by assembling fabricated parts into final products.

- Logistics and Delivery: Helping clients streamline their supply chain by offering transportation and delivery services.

- Consultation and Support: Offering expertise on material selection and process optimization to improve project outcomes.

Choosing the Right Metal Manufacturer in Edmonton

Finding the right metal manufacturer in Edmonton requires careful consideration of a variety of factors. The following sections outline key criteria to ensure you partner with a reliable and capable fabricator.

Factors to Consider for Quality and Reliability

When evaluating potential manufacturers, consider the following factors:

- Experience and Reputation: Investigate the manufacturer’s history and industry standing. Established companies often have proven track records.

- Certifications: Confirm that the manufacturer adheres to relevant industry standards and possesses necessary certifications.

- Technology and Equipment: Assess the technology the manufacturer uses; modern, automated equipment generally leads to superior quality and efficiency.

- Customer Service: Engage with their customer service to determine responsiveness, willingness to support, and overall communication skills.

Comparing Competitor Offerings

It’s vital to compare the offerings of various competitors within Edmonton. This can include examining their production capabilities, types of metals processed, pricing structure, and additional services provided. A structured review can involve:

- Requesting quotes from multiple suppliers for similar services.

- Reviewing case studies or project portfolios to gauge the quality of past work.

- Looking at third-party customer reviews or testimonials available online.

Customer Testimonials and Success Stories

Customer testimonials provide invaluable insight into the experiences of those who have previously engaged with a metal manufacturer. Diverse success stories demonstrate how different challenges were overcome, often showcasing the manufacturer’s capabilities. When researching potential partners, look for:

- Reviews on the manufacturer’s website.

- External reviews on platforms like Yelp or Google.

- Case studies that highlight specific projects, detailing challenges, solutions, and client satisfaction.

Industry Applications of Metal Fabrication

The applications of metal fabrication are vast—impacting a spectrum of industries and everyday products. Understanding where metal fabrication fits into various sectors can inform better decisions for prospective buyers.

Custom Fabrication for Construction Projects

In the construction industry, custom metal components are crucial for buildings, bridges, and infrastructure. Metal fabricators provide essential services such as:

- Creating structural steel components to reinforce buildings.

- Fabricating metal frames for doors, windows, and enclosures.

- Producing architectural features like railings and decorative facades.

Timely delivery and adherence to quality standards are critical to keep construction projects on schedule and within budget.

Metal Fabrication in Automotive Industries

The automotive industry relies heavily on metal fabrication for parts ranging from structural supports to aesthetic components. Key applications include:

- Chassis fabrication for vehicle strength and stability.

- Engine components tailored for performance.

- Body panels that combine style with aerodynamics.

Manufacturers equipped with CNC machining capabilities can produce precise components that meet the automotive industry’s strict regulations.

Use Cases in Home and Commercial Designs

Metal fabrication extends beyond industrial applications and into residential and commercial projects. Common uses involve:

- Custom furniture pieces that blend functionality with design.

- Architectural details in homes like custom staircases or decorative railings.

- Commercial fixtures such as display racks and signage.

The versatility of custom fabrication enables clients to achieve their vision while ensuring durability and aesthetic appeal.

Future Trends in Metal Manufacturing

As technology and societal needs evolve, so does the field of metal manufacturing. Staying abreast of trends is vital for businesses and consumers alike.

Technological Advances in Fabrication Techniques

Advancements in technology continuously enhance the efficiency and capabilities of metal fabrication. Key developments include:

- 3D Printing: Offering rapid prototyping and unique design capabilities that traditional techniques may not allow.

- Automation: Streamlining repetitive tasks reduces labor costs and improves precision.

- Software Innovations: Advanced software tools enable better design and simulation, enhancing planning and execution stages.

Sustainability and Eco-Friendly Practices

The push for sustainability is affecting manufacturing processes across all industries, including metal fabrication. Key practices include:

- Using recycled materials to reduce waste and resource consumption.

- Implementing energy-efficient machinery to lower carbon footprints.

- Optimizing manufacturing processes to minimize excess material waste.

Companies adopting these green initiatives often see enhanced brand reputation and compliance with regulations as society increasingly values eco-friendly practices.

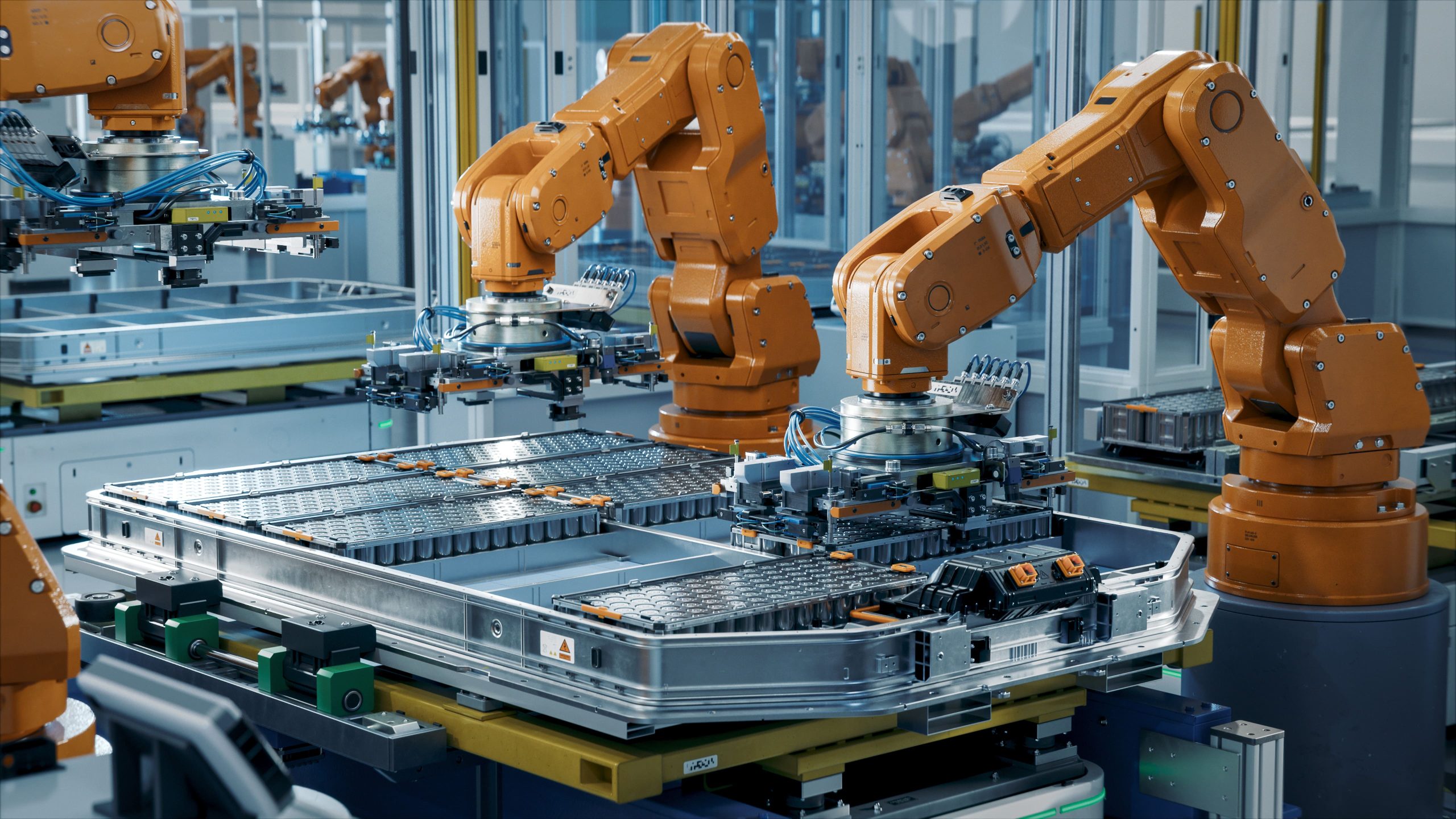

The Emerging Role of Automation in Metal Manufacturing

Automation is revolutionizing manufacturing through increased efficiency, reduced human error, and enhanced production speeds. The integration of robotics and AI in processes can lead to significant improvements in manufacturing workflows. However, the strategic implementation of automation comes with considerations such as workforce training and technology integration.