Understanding 24v Solenoid Coils

24v solenoid coils are essential components in numerous industrial applications, designed to convert electrical energy into electromagnetic force. This force actuates mechanical movement, enabling the control of various devices. By understanding their functionality, applications, and advantages, businesses can harness these components effectively.

Definition and Functionality

A solenoid coil is essentially a coil of wire that generates a magnetic field when an electric current passes through it. In the case of 24v solenoid coils, the voltage of 24 volts indicates the electrical energy required to activate the coil. This activation causes the core of the solenoid to move, which, in turn, can open or close valves, activate mechanical switches, or initiate other forms of movement in a controlled manner. The simplicity of their operation, combined with versatile applications, makes solenoid coils indispensable in modern engineering.

Applications in Various Industries

24v solenoid coils find utility across a variety of sectors. Some prominent applications include:

- Automotive: In vehicles, solenoids are employed for starting motors, locking mechanisms, and fuel management systems.

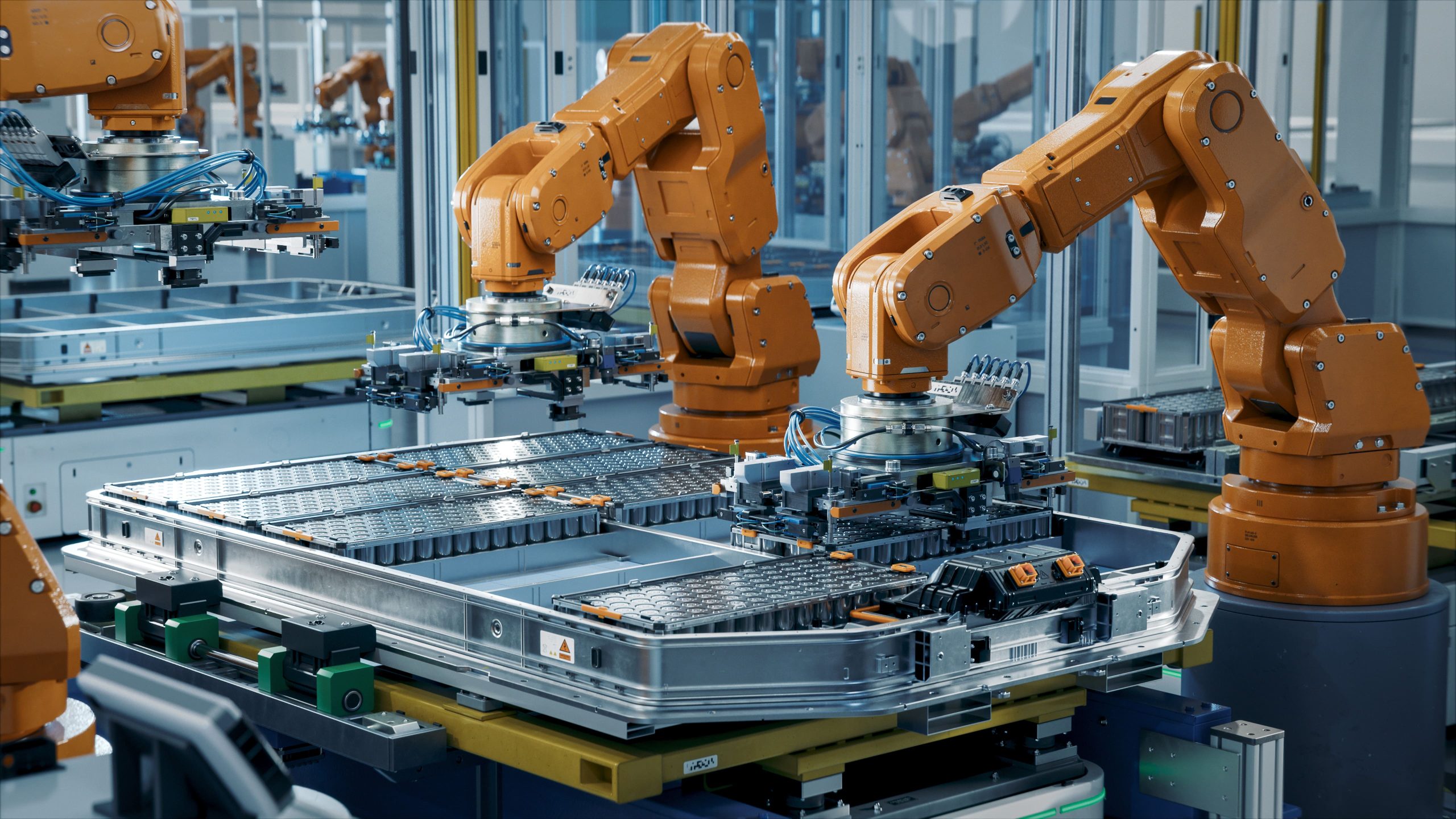

- Manufacturing: These coils control valves in hydraulic systems and are integral to automated machinery, ensuring processes occur smoothly and effectively.

- Aerospace: In aerospace applications, solenoid coils manage various systems including landing gear operations and fuel control systems.

- Medical equipment: Many medical devices utilize solenoid coils for precise control in diagnostics and treatment mechanisms.

- HVAC systems: In heating, ventilation, and air conditioning systems, they are used to control dampers and valves, allowing for efficient temperature regulation.

Benefits of Using 24v Solenoid Coils

The adoption of 24v solenoid coils offers several advantages:

- Efficiency: Operating at 24 volts reduces energy consumption while maintaining performance, making them a cost-effective choice for industries.

- Precise Control: They allow for fine control over mechanical actions, crucial in applications requiring exact operations.

- Reliability: Designed for durability, 24v solenoid coils can withstand harsh environments, contributing to long-term reliability in industrial settings.

- Easy Integration: These coils can be easily integrated into existing systems, facilitating upgrades without requiring significant overhauls.

Types of 24v Solenoid Coils

Electromagnetic vs. Pneumatic Coils

Solenoid coils can be broadly classified into two categories: electromagnetic and pneumatic, each serving different functions based on the requirements of application.

Electromagnetic Coils: These are the most common type, utilizing an electric current to create a magnetic field that generates mechanical motion. They are widely used in valves and other automated systems.

Pneumatic Coils: These coils operate by controlling the flow of compressed air or gases. They are commonly found in systems that require rapid actuation and are often used in robotics and manufacturing processes.

DC vs. AC Solenoid Coils

In addition to the electromagnetic and pneumatic categorization, solenoid coils can also differ based on the type of current they utilize:

DC Solenoid Coils: Operating with direct current, these coils are used in applications requiring consistent current and minimal energy consumption. The 24v solenoid coils discussed primarily fall into this category.

AC Solenoid Coils: Alternating current coils are designed for applications that involve variable frequencies and voltages. They are often used in larger industrial systems.

Size and Configuration Variations

24v solenoid coils come in various sizes and configurations to fit specific needs. Proper selection is crucial for optimal performance. Factors influencing these choices include:

- Mounting type: Solenoids can be designed for panel mounting, direct integration into machinery, or remote operation.

- Coil dimension: The size of the coil typically takes into account the required power, space constraints, and the mechanism it will control.

- Operating environment: Coils designed for harsh conditions may require additional protective housing to guard against external factors such as moisture and dust.

Installation and Maintenance

Installation Best Practices

To ensure optimal performance from 24v solenoid coils, installation must be carried out meticulously:

- Correct Placement: Ensure that the coil is positioned according to design specifications, allowing for proper actuation of the mechanical component.

- Electrical Connections: Use quality connectors and ensure that wiring is secured and insulated to prevent short circuits.

- Test Functionality: Conduct tests post-installation to ensure the solenoid responds correctly to electrical input.

Common Maintenance Issues

Routine maintenance can prevent failure. Common issues include:

- Overheating: This may occur due to prolonged use or inadequate cooling solutions, leading to reduced coil lifespan.

- Corrosion: Exposure to harsh environments may lead to rust, affecting functionality. Regular inspections can mitigate this risk.

- Wiring Failures: Damaged wires can disrupt power supply. Regular checks can help identify potential failures early.

Tips for Extending Coil Lifespan

To prolong the lifespan of 24v solenoid coils, consider the following tips:

- Thermal Management: Ensure coils operate within recommended temperature limits to prevent premature burnout.

- Regular Inspections: Schedule routine checks for signs of wear, damage, or wear on electrical connections.

- Proper Voltage Use: Ensure the coil operates only at specified voltage levels to avoid stressing the system.

Performance Analysis

Measuring Coil Efficiency

Efficiency can be measured by assessing how effectively a solenoid coil converts electrical energy into mechanical action:

- Power Consumption: Monitoring the wattage used during operation can provide insights into energy efficiency.

- Response Time: The speed at which the coil actuates the desired mechanism is a critical performance metric.

- Load Handling: The ability of the solenoid to handle its rated load without overheating or failing is crucial for long-term efficiency.

Impact of Voltage Variations

Variations in voltage can significantly impact performance:

- Under-Voltage: Insufficient voltage can result in weak magnetic fields, leading to mechanical malfunction.

- Over-Voltage: This can cause overheating and ultimately damage the coil, affecting reliability and requiring replacement.

Replacement Timing and Indicators

Knowing when to replace a solenoid coil is vital. Indicators include:

- Increased Malfunctions: Frequent mechanical failures may suggest the coil is failing.

- Physical Damage: Signs of corrosion, cracks, or overheating on the coil should prompt evaluation and replacement.

- Operational Efficiency Decline: A notable drop in performance metrics can signal that replacement is necessary.

Future Trends in Solenoid Technologies

Innovations in Coil Design

The field of solenoid technology continually evolves, leading to innovations such as:

- Smarter Materials: Advancements in materials that enhance thermal conductivity and reduce weight contribute to better performance and efficiency.

- Compact Designs: Miniaturization allows solenoids to fit into tighter spaces without sacrificing performance, expanding their usability.

- Energy Harvesting: Future designs may incorporate energy harvesting technologies, reducing reliance on external power sources.

Integration with Smart Systems

As industries move towards automation and smart solutions, solenoid coils are increasingly being integrated into interconnected systems:

- IoT Compatibility: Integration with Internet of Things (IoT) systems allows for remote monitoring and control, enhancing decision-making processes.

- Data Analytics: Utilizing data from solenoid operations can inform maintenance schedules and improve operational efficiencies.

Regulatory Changes Impacting Usage

Lastly, various regulatory changes may affect the use of solenoid coils:

- Energy Efficiency Standards: New regulations may promote or mandate the use of more energy-efficient solenoids, influencing design and sourcing decisions.

- Environmental Compliance: Stricter regulations around materials and production processes may encourage manufacturers to adopt greener practices.