Understanding Adhesive Films in Modern Applications

Adhesive films have emerged as a fundamental component in various industries, particularly in areas requiring strong, reliable bonding solutions. From aerospace to automotive, these materials offer unique advantages that enhance performance, durability, and efficiency. At the heart of this technology is a variety of specialized adhesive films that are pre-engineered to meet the stringent demands of modern manufacturing and production processes. The introduction of precision-cast adhesive films has revolutionized how components are bonded, providing clean and consistent results. For additional information on these innovative products, visit https://www.makobond.com/adhesives-films.

The Role of Adhesive Films in Aerospace and Automotive

The aerospace and automotive industries demand materials that can withstand extreme conditions while providing excellent bonding capabilities. Adhesive films play a crucial role in the construction and maintenance of various components, from lightweight structures to complex assemblies. In the aerospace sector, these films ensure lightweight construction, which is vital for fuel efficiency. They also contribute to the structural integrity of materials subjected to high stress and fluctuating temperatures.

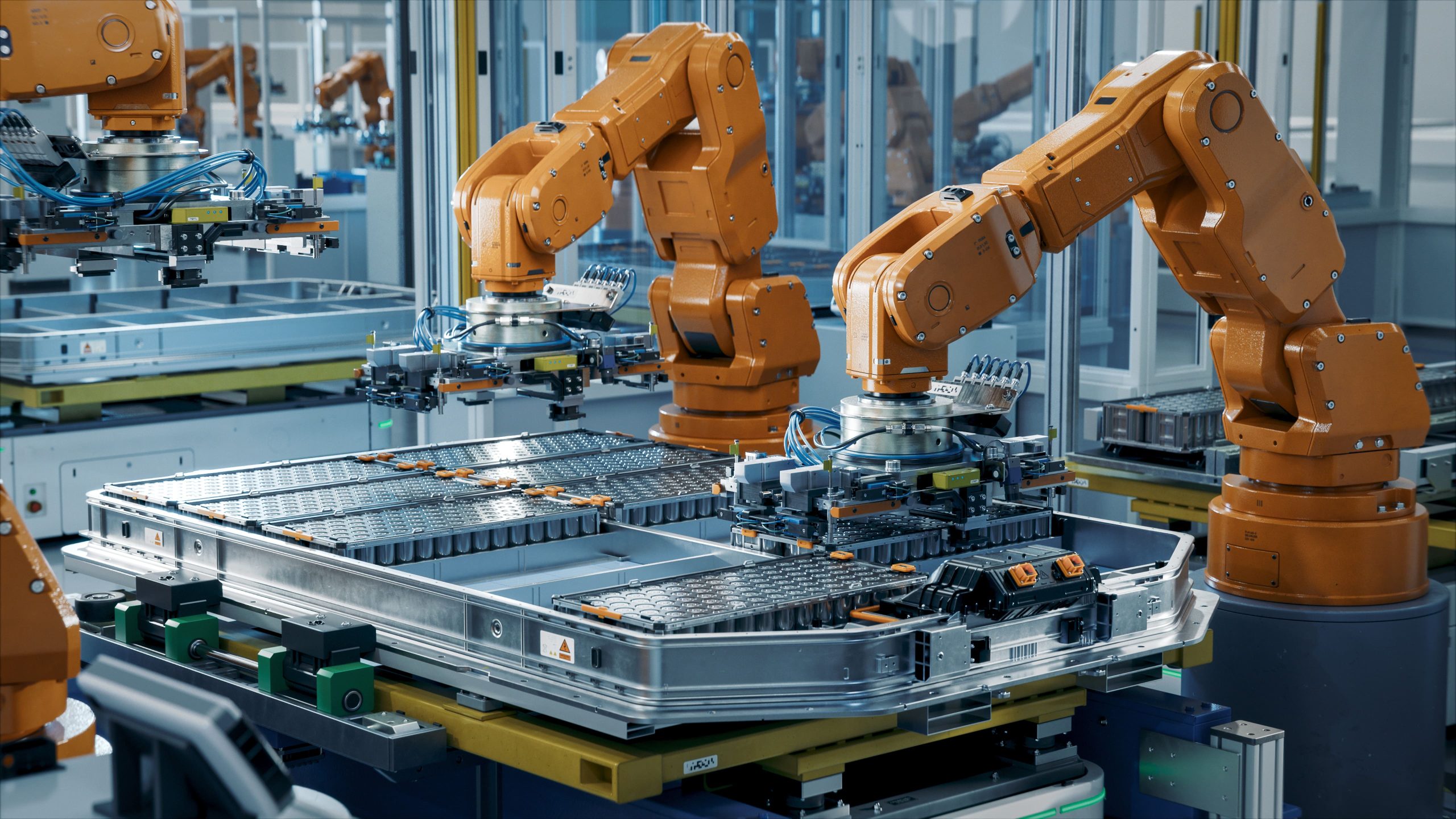

In automotive applications, adhesive films are utilized for their ability to adhere dissimilar materials, ensuring that metals, composites, and plastics bond effectively. This versatility enables the production of lightweight vehicles without compromising strength, contributing to improvements in fuel efficiency and overall performance.

Types of Adhesive Films and Their Uses

Several types of adhesive films are available, each designed to address specific bonding needs. Common types include:

- Thermoplastic films: These are activated by heat and offer flexibility and ease of use in production processes.

- Thermosetting films: These films are permanently bonded after activation, providing exceptional durability and heat resistance.

- Pressure-sensitive films: These allow for easy application and repositioning, making them ideal for situations where adjustments are necessary.

These variations adapt to different applications, from structural bonding to decorative elements, ensuring that manufacturers can select the right film for their specific needs.

Benefits of Utilizing Precision-Cast Adhesive Films

Precision-cast adhesive films offer numerous benefits that make them an attractive option for manufacturers. Key advantages include:

- Enhanced Adhesion: They provide superior bonding strength compared to traditional adhesives, ensuring components stay securely bonded even under stress.

- Clean Application: Being pre-formed on a carrier film, they minimize mess and simplify application processes, leading to cleaner production environments.

- Controlled Thickness: This allows for consistent performance across applications, reducing the risk of weak points in the bond.

- Reduced Curing Time: Many adhesive films can bond quickly under heat and pressure, accelerating production timelines without sacrificing quality.

These benefits position precision-cast adhesive films as a preferred choice for high-performance applications across various sectors.

Key Considerations When Choosing Adhesive Films

Evaluating Performance Metrics for Adhesive Films

When selecting adhesive films, it’s essential to evaluate performance metrics such as shear strength, peel strength, and environmental resistance. These metrics provide insights into how the adhesive will perform under various conditions. For instance, shear strength indicates the amount of stress the bond can withstand before failing, while peel strength measures how well the adhesive can resist being pulled apart.

Environmental resistance is also crucial, as it determines how the adhesive interacts with different factors like heat, humidity, and chemicals. Manufacturers should select films that meet or exceed the requirements of the specific application to ensure longevity and reliability.

Material Compatibility and Application Techniques

Another critical consideration is material compatibility. Different adhesive films interact uniquely with various substrates, including metals, composites, and plastics. Understanding the chemical and physical properties of both the adhesive film and the materials being bonded will help ensure a successful application.

Moreover, employing the correct application techniques is vital for optimal performance. This involves preparing the surfaces to be bonded by cleaning and possibly roughening them to enhance adhesion. Correct temperature and pressure settings during the bonding process can significantly influence the resulting bond strength.

Cost-Effectiveness vs. Performance

While initial costs are always a consideration, manufacturers must also consider the long-term benefits of investing in high-quality adhesive films. Cheaper alternatives may seem appealing initially but can lead to greater expenses down the line due to failures, rework, and product returns. Assessing the return on investment (ROI) from utilizing high-performance adhesive films can provide a clearer picture of their value.

Additionally, evaluating total cost of ownership, which includes maintenance, training, and the potential for increased productivity, can help companies make informed decisions about adhesive film selection.

Application Techniques for Adhesive Films

Surface Preparation for Optimal Bonding

Proper surface preparation is vital for achieving optimal bonding performance with adhesive films. This process typically involves the following steps:

- Cleaning: Remove contaminants such as oil, dust, and moisture from the bonding surfaces to prevent interference with adhesive performance.

- Roughening: Mechanically altering the surface to create micro-abrasions can improve adhesive interlocking and bond strength.

- Drying: Ensure that surfaces are completely dry before application to avoid compromising bond integrity.

By following these steps, manufacturers can maximize the effectiveness of adhesive films in their projects.

Heat and Pressure Activation Methods

Many adhesive films require heat or pressure activation for bonding. Understanding the specific requirements for each film type is essential to achieving the best results. For heat-activated films, manufacturers often use ovens or heat lamps to deliver consistent temperatures across the bonding surface. Pressure-sensitive films may require tools such as rollers or presses to ensure even pressure is applied.

Attention to activation parameters ensures that the adhesive reaches its optimal bonding state, which is crucial for high-performance applications.

Common Mistakes to Avoid

While working with adhesive films, manufacturers may encounter several common pitfalls that can impact bond performance. Here are some mistakes to watch out for:

- Neglecting Surface Preparation: Skipping cleaning and roughening can lead to weak bonds.

- Inconsistent Activation: Failing to maintain uniform heat or pressure can create weak points in the bond.

- Using Incorrect Films: Selecting a film incompatible with the substrate can lead to product failures.

By avoiding these mistakes, manufacturers can enhance the reliability and effectiveness of their bonding processes.

Adhesive Films in Emerging Technologies

Advancements in Adhesive Film Technology

As technology continues to evolve, so do adhesive films, with innovations focused on improving performance and application flexibility. Recent advancements include the development of films that can respond to environmental changes, providing dynamic bonding capabilities that adapt to their surroundings.

Research and development initiatives are also examining bio-based materials for adhesive films, promoting sustainability without sacrificing performance. These innovations promise to shape the future of adhesive technology, making it more efficient and environmentally friendly.

Case Studies of Innovative Applications

There are numerous examples showcasing how advanced adhesive films have been effectively utilized in innovative applications. For instance, in aerospace, a lightweight adhesive film was employed to bond composite wing structures, resulting in enhanced aerodynamic performance and weight savings.

In automotive manufacturing, a cutting-edge adhesive film was developed to bond multi-material components in vehicle assemblies, enabling automakers to create vehicles that are lighter and more energy-efficient. These case studies highlight the critical role that adhesive films play in driving advancements in manufacturing processes and product designs.

The Future of Adhesive Films in Manufacturing

The future of adhesive films looks promising as ongoing research and innovation continue to push the boundaries of what is possible. With increased focus on sustainable practices, the trend towards biocompatible and recyclable adhesive films is likely to gain traction. Moreover, the integration of smart technologies into adhesive films could lead to real-time monitoring of bond quality and environmental conditions, further enhancing reliability.

Manufacturers who leverage these advancements are well-positioned to gain a competitive edge in their respective industries.

Maximizing Performance with Proper Maintenance

Best Practices for Storing Adhesive Films

Proper storage of adhesive films can significantly impact their performance and shelf life. Here are some best practices for storage:

- Temperature Controls: Store films in a cool, dry place away from direct sunlight.

- Humidity Management: Maintain an appropriate humidity level to prevent moisture absorption that can compromise film integrity.

- Proper Packaging: Ensure that adhesive films are kept in original packaging or sealed containers to protect from contaminants.

Implementing these storage practices can extend the usability and effectiveness of adhesive films.

Maintaining Product Integrity Over Time

To ensure long-term performance, manufacturers need to periodically check adhesive films for signs of degradation or contamination. Regular inspections can help identify issues before they lead to failures in bonding. Additionally, adhering to recommended usage timelines and replacement intervals can ensure that the adhesives remain effective throughout their lifecycle.

Recycling and Environmental Considerations

As industries move towards more sustainable practices, recycling adhesive films is becoming an important consideration. Ensuring that materials are disposed of responsibly reduces environmental impact and promotes resource conservation. Efforts are underway within the industry to develop recycling processes specifically for adhesive films, further supporting sustainability goals.

By embracing these environmental considerations, manufacturers can contribute positively to ecological preservation while still benefitting from the high performance of adhesive films.