Understanding Electromagnetic Shielding Materials

Electromagnetic shielding materials are essential components in the modern technological landscape, serving a critical function in protecting devices and sensitive equipment from excessive electromagnetic interference (EMI). These materials shield electronic components from noise generated by electromagnetic fields, ensuring optimal performance and longevity of electronic devices. By reducing electromagnetic interference, these materials enhance functionality in various applications ranging from consumer electronics to medical equipment and telecommunications.Electromagnetic shielding materials prevent performance degradation and provide a safeguard for users and the environment.

What are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are engineered substances designed to obstruct the electromagnetic fields from interfering with electronic circuits. These materials can broadly be classified into conductive and magnetic materials, which provide effective shielding against both electric and magnetic fields. Common materials chosen for their shielding properties include metals like copper, aluminum, nickel, and steel, as well as composite materials and specialized coatings.

How Electromagnetic Shielding Works

The principle behind electromagnetic shielding lies in the ability of certain materials to reflect, absorb, or reroute electromagnetic waves. When these waves encounter a conductive material, several phenomena occur: the wave is reflected back, absorbed, or dissipated in the material, thereby preventing it from penetrating through. The effectiveness of shielding is often quantified using metrics such as the attenuation level, which is measured in decibels (dB), indicating how much of the electromagnetic wave has been reduced.

Common Applications of Shielding Materials

Electromagnetic shielding materials find applications in various fields, including:

- Consumer Electronics: Shielding is vital for devices like smartphones, tablets, and laptops to maintain performance in the face of radio frequency interference (RFI).

- Medical Equipment: In hospitals, devices such as MRI machines require effective shielding to prevent interference from external electromagnetic waves, ensuring accurate readings.

- Telecommunications: Base stations and antennas often use shielding materials to minimize electromagnetic leakage and protect signal integrity.

- Automotive Applications: Modern vehicles incorporate sophisticated electronics that need shielding to prevent EMI from impacting performance.

Types of Electromagnetic Shielding Materials

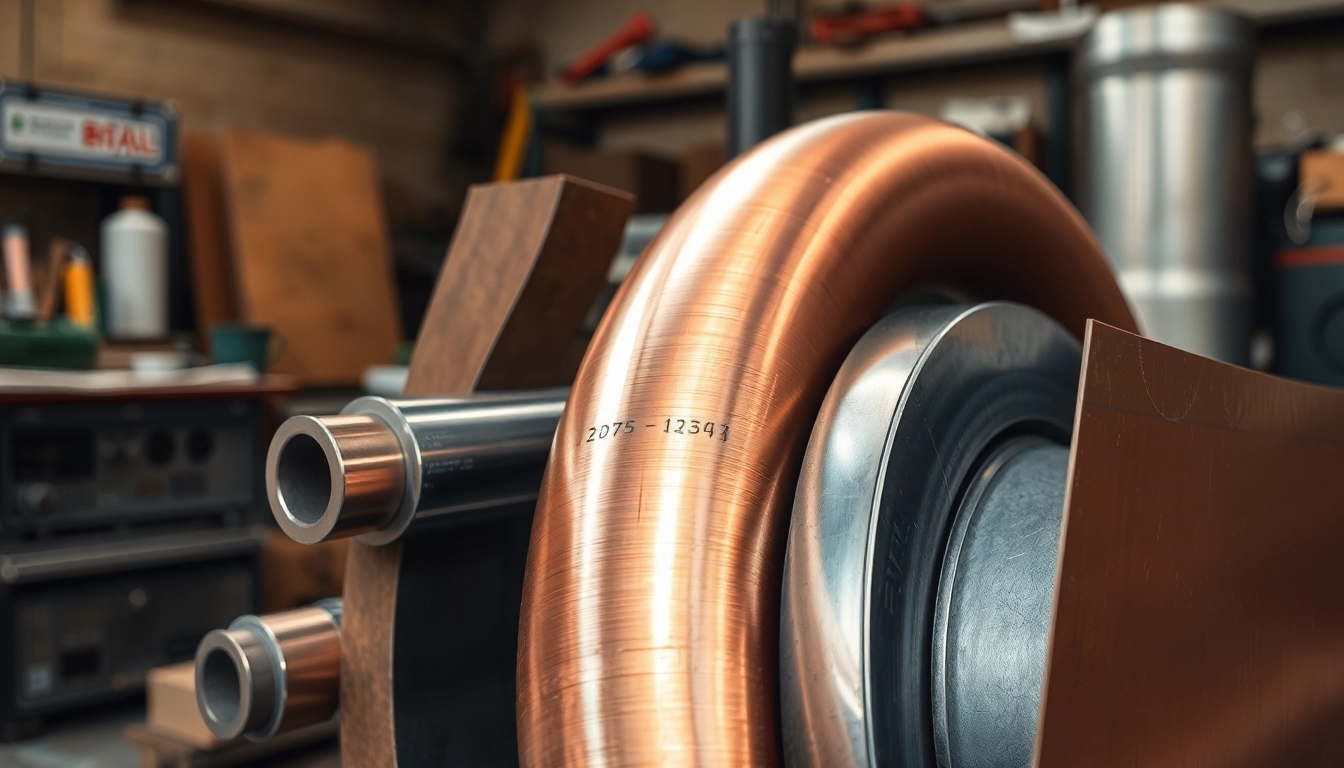

Conductive Metals in EMI Shielding

Conductive metals are the most widely used materials for EMI shielding due to their high electrical conductivity. The most effective metals include:

- Copper: Recognized for its excellent conductivity and effectiveness in attenuating both electrical and magnetic interference.

- Aluminum: A lightweight and cost-effective option, often used in flexible shielding applications.

- Nickel: Often combined with other metals, nickel enhances corrosion resistance in shielding applications.

- Steel: Commonly used for its strength and durability, particularly in tough environmental conditions.

Each of these materials offers distinct advantages depending on the application, such as weight, cost, and strength considerations.

Composite and Nanomaterials for Shielding

Advances in material science have led to the development of composite materials and nanocomposites, which combine two or more materials to enhance performance. These materials can include polymers infused with metal particles, allowing for flexibility and lightweight characteristics while retaining strong shielding capabilities.

Nanotechnology has introduced materials like carbon nanotubes and graphene, which exhibit remarkable conductive properties and can be integrated into various applications, paving the way for innovative shielding solutions.

Flexible and Rigid Shielding Options

Electromagnetic shielding materials can also be categorized based on their physical properties:

- Flexible Shielding: These include fabric and conductive foams, which are ideal for applications requiring conformability, such as wraps for cables or enclosures in tight spaces.

- Rigid Shielding: Typically made from sheet metal or rigid casing, these materials are best suited for enclosures that require structural integrity and substantial attenuation.

The choice between flexible and rigid shielding often comes down to the specific project requirements, including environmental conditions and physical constraints.

Factors to Consider When Choosing Shielding Materials

Effectiveness Against Different Frequencies

Electromagnetic interference encompasses a wide variety of frequencies. When selecting shielding materials, it’s crucial to consider the range of frequencies specific to the application. Materials with high conductivity are generally more effective against high-frequency electromagnetic waves, while permeability is crucial for low-frequency magnetic fields. Experts typically evaluate shielding effectiveness with respect to frequency ranges listed in standardized testing.

Material Durability and Environmental Resistance

Electromagnetic shielding materials, especially those used in harsh environments, must also withstand adverse conditions such as humidity, temperature variations, and exposure to chemicals. Selecting a material with proven environmental resistance can extend the lifespan of the shielding and maintain overall system performance. Corrosion-resistance and mechanical toughness should factor significantly into the material selection process.

Cost Considerations for EMI Shielding

While the performance of shielding materials is essential, cost is also a significant factor. The balance between material performance and budget constraints must be assessed carefully. Often, lower cost materials might suffice for less demanding applications, while high-performance materials are essential for critical environments where failure is not an option. Analyzing lifetime cost, including installation and maintenance, can provide a fuller picture of affordability.

Best Practices for Implementing Electromagnetic Shielding

Designing Shielding Solutions for Various Applications

Creating effective shielding usually requires a thoughtful design phase where potential interference sources and signal paths are identified. A successful design approach often includes:

- Identifying potential EMI sources in the environment,

- Using simulation tools to model electromagnetic fields,

- Implementing appropriate grounding techniques, and

- Ensuring physical continuity of the shielding throughout the design.

Collaboration with engineers during the design phase can improve shielding effectiveness and ensure compliance with electromagnetic compatibility (EMC) standards.

Testing and Certification of Shielding Materials

Once shielding materials have been selected and solutions are implemented, rigorous testing is necessary to confirm their effectiveness. Standards such as MIL-STD-285 and IEEE 299 provide guidelines on testing methods and help ensure that designs meet applicable regulatory requirements. Certification from recognized authorities may also be essential, especially in industries such as aerospace and healthcare.

Common Mistakes in EMI Shielding Implementation

Several common pitfalls can lead to ineffective shielding solutions. These include:

- Neglecting to consider the form factor of the electronic assembly,

- Overlooking ventilation and thermal management,

- Inadequate grounding practices, and

- Using shielding materials that do not suit the frequency of interest.

Addressing these mistakes early in the design and implementation process can save significant costs and minimize risks related to EMI.

Future Trends in Electromagnetic Shielding Materials

Advancements in Material Science for Shielding

The field of electromagnetic shielding is witnessing rapid advancements, particularly with the integration of smart materials that change characteristics in response to external stimuli. Research is ongoing into developing hybrid materials combining natural fibers with metallic fibers to optimize performance while reducing environmental impact.

Emerging Technologies Impacting EMI Shielding

Technologies such as 5G and the Internet of Things (IoT) are driving the need for improved electromagnetic shielding solutions. As devices become more interconnected, the potential for electromagnetic interference increases dramatically. Manufacturers will need to innovatively address these challenges through advanced materials and efficient shielding designs that meet the challenges of modern technology.

Sustainability in Electromagnetic Shielding Materials

As concerns about environmental sustainability continue to grow, there is a noticeable trend toward developing eco-friendly electromagnetic shielding materials. Manufacturers are focusing on creating recyclable or biodegradable options that don’t compromise performance. These newly developed materials aim to significantly lower the environmental impact associated with traditional shielding materials.