Understanding Low Volume PCB Assembly

Definition and Importance of Low Volume PCB Assembly

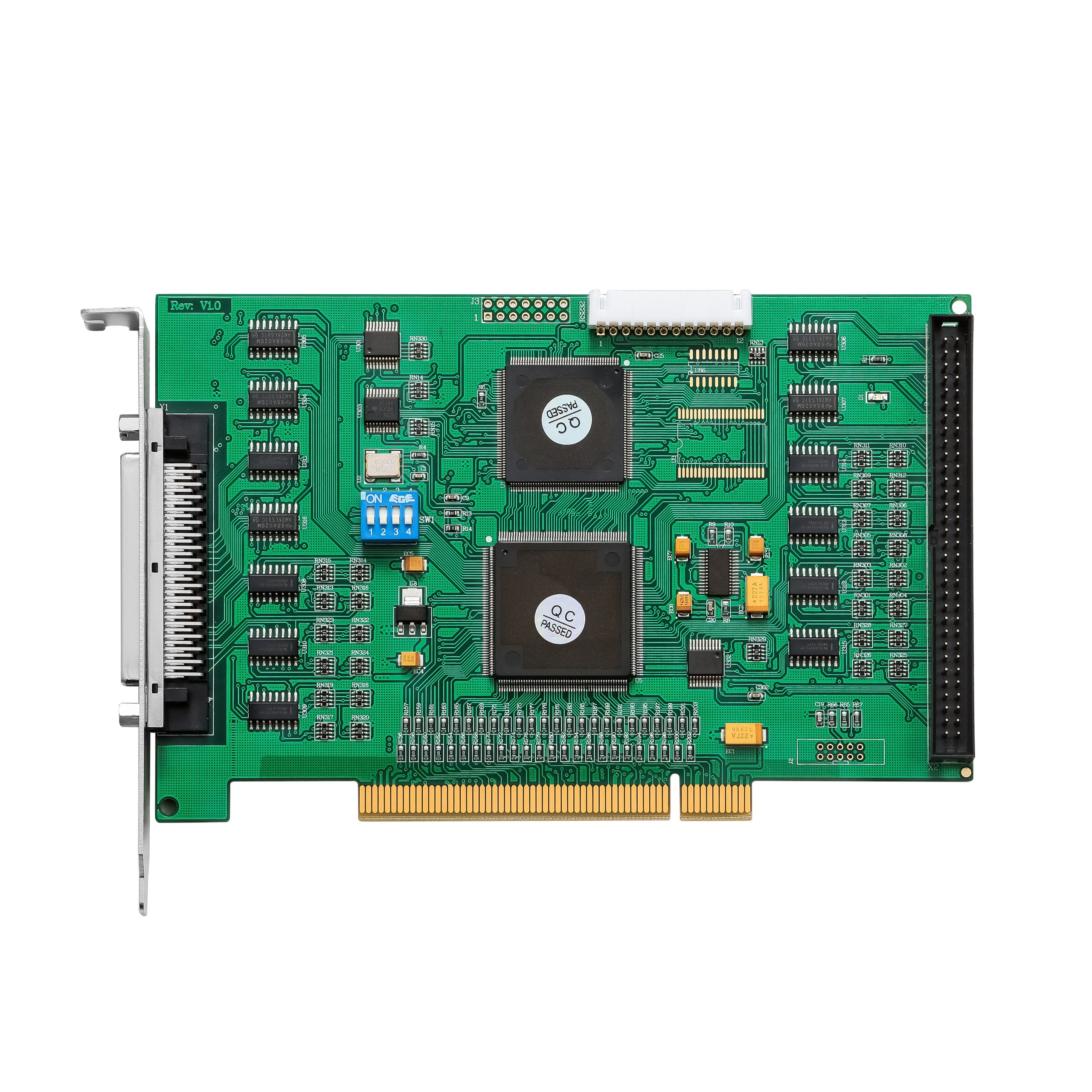

Low Volume PCB Assembly refers to the manufacturing process of printed circuit boards (PCBs) in small quantities, typically ranging from one to several hundred units. Unlike mass production techniques, which focus on large-scale output and cost efficiency, low volume assembly emphasizes flexibility, customization, and rapid turnaround times. This approach is critical for companies looking to prototype new designs, conduct small batch runs, or respond to niche market demands.

The importance of Low Volume PCB Assembly can be attributed to several factors:

- Prototyping: It allows companies to bring new electronic products to market quickly by testing designs before committing to larger production runs.

- Customization: Small manufacturers or startups can create tailored solutions that meet specific requirements without incurring prohibitive costs.

- Market Responsiveness: Companies can pivot quickly to adapt to new trends or consumer demands, ensuring they remain competitive.

By integrating Low Volume PCB Assembly into their manufacturing strategies, businesses can optimize their product development cycles and enhance their responsiveness to market changes.

Applications and Industries Utilizing Low Volume PCB Assembly

Various industries benefit from Low Volume PCB Assembly, spanning fields where both innovation and precision are paramount.

- Consumer Electronics: Startups and emerging tech companies often rely on low volume runs for product launches and limited editions.

- Aerospace and Defense: Specialized components necessitate rigorous quality assurance and often require low quantities of complex PCBs.

- Medical Devices: Custom electronic solutions are critical in medical applications, making low volume production ideal for new technologies that are still in the testing phase.

- Automotive: As vehicles become more integrated with technology, low volume PCB assembly supports innovative features, enabling manufacturers to test and implement new designs swiftly.

- IoT Devices: The Internet of Things demands flexibility; low volume assembly allows for the rapid deployment of unique devices that meet various specifications.

Key Advantages of Low Volume PCB Assembly

Low Volume PCB Assembly presents a range of advantages tailored to specific business needs:

- Cost-Effectiveness: It minimizes overhead costs by avoiding the significant capital investment associated with high-volume production.

- Flexibility and Agility: Manufacturers can quickly adjust to changing designs or specifications, ensuring that products remain competitive in the fast-paced electronics market.

- Quality Focus: With smaller production runs, there is an enhanced focus on quality assurance, reducing the likelihood of defects in final products.

- Shorter Lead Times: Low volume production enables quicker turnaround times, facilitating rapid prototyping and market testing.

- Iterative Development: Companies can employ an iterative design approach, making continuous improvements based on testing and feedback from low volume runs.

Steps to Achieve Quality Low Volume PCB Assembly

Design Considerations for Low Volume PCB Assembly

Effective design is essential for successful Low Volume PCB Assembly. Key considerations include:

- Design for Manufacturability (DfM): Optimize layouts to minimize complexities, ensuring easy assembly and reducing the potential for errors.

- Component Placement: Strategic placement can enhance both workflow efficiency and soldering quality, which are critical in low volume runs.

- Testing and Verification: Designing PCBs for easy accessibility during testing phases can save time and improve reliability.

Component Selection and Sourcing Strategies

The selection and sourcing of components significantly impact the success of Low Volume PCB Assembly:

- Quality Over Cost: Prioritize components from reliable suppliers to ensure performance and reliability, even at higher costs.

- Diverse Sourcing: Establish relationships with multiple suppliers to mitigate risk and ensure a steady flow of essential components.

- Lead Time Management: Keep track of component availability and his ensure timely procurement to match production schedules.

Manufacturing Processes Overview

The manufacturing process for Low Volume PCB Assembly involves several key steps:

- PCB Fabrication: Includes etching, drilling, and layering required to create the physical circuits.

- Solder Paste Application: Precision application of solder paste onto pads, normally using a stencil.

- Pick and Place: Automated or manual placement of components onto the PCB according to design specifications.

- Soldering: Utilizing reflow ovens or wave soldering techniques to permanently attach components to the board.

- Testing: Conducting rigorous testing to ensure quality and functionality before packaging.

Best Practices for Low Volume PCB Assembly

Optimizing Workflow for Efficiency

To enhance productivity during Low Volume PCB Assembly, manufacturers should consider:

- Lean Manufacturing Principles: Implement strategies to minimize waste and maximize value at every stage of the assembly process.

- Workstation Organization: Streamlining workstations can significantly reduce unnecessary movements, thus improving overall efficiency.

- Employee Training: Invest in training for operators to decrease errors and improve the quality of output.

Quality Control Measures and Testing Methods

Establishing robust quality control measures is vital to ensure high-quality outcomes:

- Incoming Material Inspection: Perform thorough inspections of all components upon arrival at the facility to catch discrepancies early.

- In-Process Inspections: Regularly check assemblies during production to identify and correct issues as they arise.

- Final Testing: Conduct rigorous functional and electrical testing following assembly to confirm that the PCB meets specified performance criteria.

Cost Management Strategies

Managing costs effectively is crucial in Low Volume PCB Assembly:

- Accurate Estimations: Work closely with suppliers and manufacturers to provide precise quotations and prevent unexpected costs.

- Volume Discounts: While operating at low volumes, seek suppliers that offer cost-effective solutions for component purchases.

- Process Optimization: Regularly evaluate processes for improvements that can lead to cost reductions without sacrificing quality.

Challenges and Solutions in Low Volume PCB Assembly

Common Challenges Faced in Low Volume PCB Assembly

Despite its advantages, Low Volume PCB Assembly does face notable challenges:

- Component Availability: Sourcing components for small runs can be more complex and time-consuming than in high volume productions.

- Quality Assurance: Maintaining quality amid diverse product specifications can be challenging.

- Lead Time Issues: Achieving quick turnaround times while managing production complexity often requires meticulous planning.

Innovative Solutions to Overcome Obstacles

To address the challenges faced during Low Volume PCB Assembly:

- Supplier Relationships: Cultivating strong partnerships with suppliers can mitigate risks of component shortages and lead times.

- Advanced Manufacturing Techniques: Employing technologies such as additive manufacturing can help streamline processes and reduce costs.

- Collaborative Design Processes: Engage multidisciplinary teams during design phases to identify potential issues early.

Case Studies of Successful Low Volume PCB Assembly Projects

Real-world examples can illustrate the efficacy of Low Volume PCB Assembly:

- Medical Device Development: A company specializing in medical implants utilized low volume assembly to test various configurations, leading to breakthroughs in device performance.

- Electronic Prototypes: An emerging tech company rapidly iterated on their smart device design by leveraging low volume assembly, significantly improving user feedback and market acceptance.

The Future of Low Volume PCB Assembly

Technological Advancements Impacting Low Volume PCB Assembly

Looking ahead, several technological advancements are poised to revolutionize Low Volume PCB Assembly:

- Automation: Increased automation in assembly processes can enhance efficiency and consistency, further driving down costs.

- Artificial Intelligence: AI and machine learning systems can optimize supply chains, predict failures, and even streamline design processes.

- Sustainable Practices: The rise of green electronics is driving demand for eco-friendly materials and energy-efficient manufacturing practices.

Market Trends and Predictions

The future landscape of Low Volume PCB Assembly is likely to witness the following trends:

- Increased Demand for Customization: As consumer expectations evolve, the need for tailored solutions is expected to grow.

- Prototyping as a Service: More companies will look for partners that can offer quick-turn prototyping capabilities to remain competitive.

- Integration of IoT Solutions: With the explosion of Internet of Things devices, low volume production will be increasingly essential in meeting diverse customer needs.

Preparing for Evolving Customer Needs

To remain relevant and competitive, companies involved in Low Volume PCB Assembly must:

- Stay Informed: Regularly monitor industry trends and technological advancements to adjust strategies accordingly.

- Engage Customers: Actively seek feedback from partners and end-users to tailor production processes and product offerings.

- Invest in Talent: Cultivating expertise in both engineering and manufacturing will be essential for addressing future challenges.