Understanding the Needle Gun: What It Is and How It Works

The needle gun is a powerful tool in surface preparation, designed to remove unwanted materials from metal surfaces. Its unique mechanism operates using rapidly vibrating needles to effectively strip away rust, paint, and welding slag, making it an essential piece of equipment in various industries, including manufacturing and automotive repair. This section will delve into the operational mechanics behind needle guns, the various types available in the market, and crucial safety considerations to keep in mind while using these powerful devices.

The Mechanism Behind Needle Guns

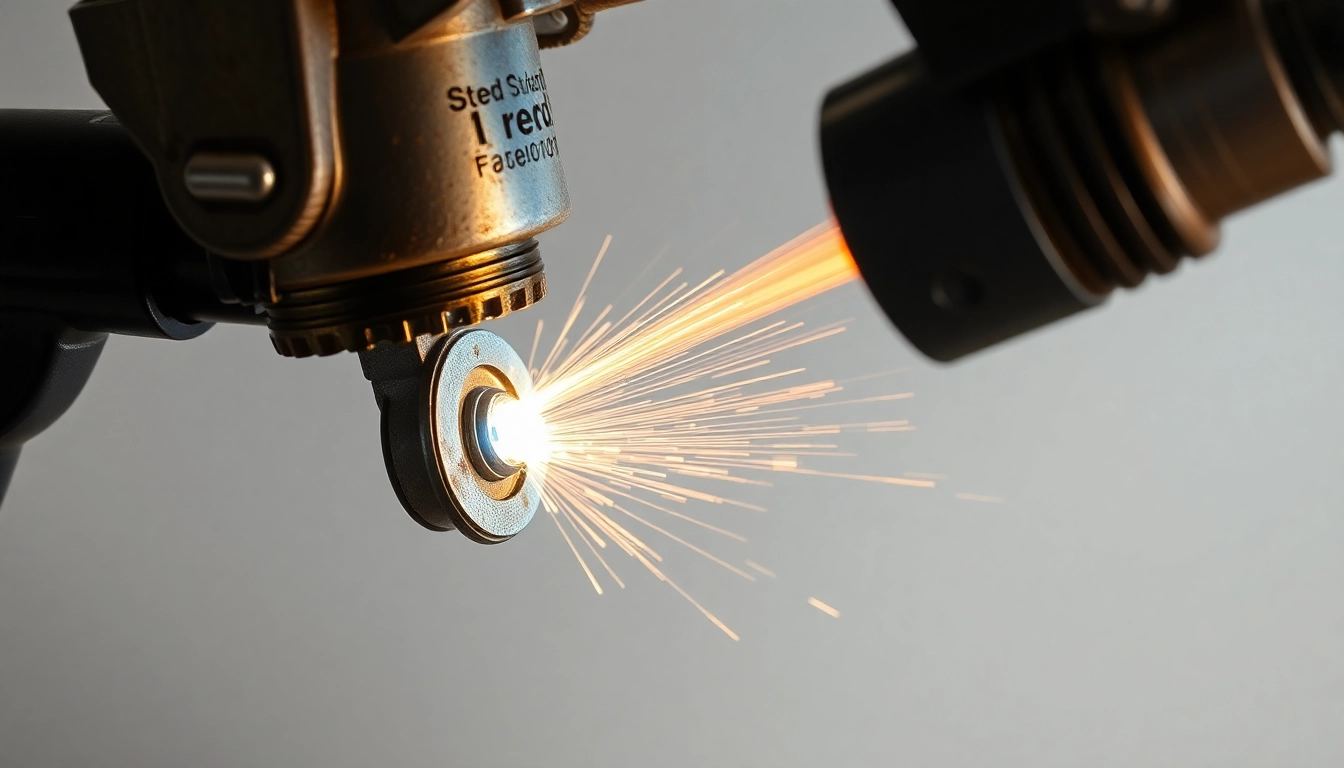

At the core of the needle gun’s functionality is its pneumatic or electric mechanism that drives a series of high-speed needles back and forth. Here’s a closer look at how it works:

- Vibration System: Needle guns typically utilize a pneumatic or electro-mechanical system to generate rapid oscillations. These vibrations are transmitted to the needles, which strike the surface at high speeds, generally between 3,000 to 4,000 blows per minute (BPM).

- Needle Configuration: The needles themselves are hardened steel rods designed to withstand extreme wear. They come in various configurations, from single-needle designs for precision work to larger multipoint arrangements (up to 20 needles) for more extensive surface preparation tasks.

- Dust Management: As the needles make contact with the surface, they dislodge contaminants like rust and paint. Many models come equipped with dust collection systems or attachments that help manager debris, ensuring a cleaner work environment.

Types of Needle Guns Available

Needle guns are classified mainly into two categories based on their power source and method of operation: pneumatic and electric.

- Pneumatic Needle Guns: This type operates using compressed air, making them powerful yet lightweight, ideal for extensive industrial applications.

- Electric Needle Guns: These models operate on electricity and are generally favored for lighter, more detailed work, providing a consistent operational power without the need for an air compressor.

There are also hybrid models that combine both power sources, giving users flexibility in how they approach different tasks.

Safety Considerations When Using Needle Guns

As with any power tool, safety should always be a top priority. Here are essential safety measures to consider when operating needle guns:

- Personal Protective Equipment (PPE): Always wear gloves, goggles, and a dust mask to protect against debris and dust that may be expelled during use.

- Noise Protection: Needle guns can be loud, often exceeding 85 decibels, so ear protection is recommended.

- Stable Work Environment: Ensure the work area is well-lit and free of obstacles to prevent accidents.

- Proper Handling: Maintain a firm grip and keep hands clear of the needle output to avoid injury.

Choosing the Right Needle Gun for Your Projects

Selecting the right needle gun requires consideration of several factors that match the tool’s capabilities with the intended tasks. This section outlines critical criteria for making a thoughtfully informed choice.

Factors to Consider in Needle Gun Selection

- Power Source: Choose between pneumatic and electric based on the nature of your work—pneumatic for heavy-duty uses or electric for more precise tasks.

- Needle Configuration: Assess the number and type of needles. A model with more needles will be more efficient for large surfaces, while a single needle may suffice for detailed jobs.

- Pressure Rating: If opting for a pneumatic model, consider the required air pressure, typically between 80-90 PSI, to achieve optimal performance.

- Portability: Evaluate weight and size, especially if the tool will be frequently transported to different job sites.

Comparing Air vs. Electric Needle Guns

Both air and electric needle guns have their advantages and drawbacks:

- Air Needle Guns: Advantageous for prolonged use due to their lighter weight and no battery issues; however, they require a constant air supply which may limit portability.

- Electric Needle Guns: Offer ease of use and are often quieter, but battery life may be a concern on extended jobs, and they may not match the raw power of pneumatic equivalents.

Assess the specific tasks ahead to determine which option aligns best with your operational needs.

Top Brands and Models of Needle Guns in 2023

The market is flooded with options from various manufacturers. Below are some top-rated models to consider in 2023:

- Von Arx 23B Needle Gun: Known for its durability and effectiveness in extreme conditions.

- Ingersoll Rand Needle Scalers: Highly regarded for their ergonomic design and robust performance.

- Chicago Pneumatic Models: Offer an extensive range suitable for various applications, praised for their dependability.

Review user feedback and specifications to ensure that you find a model that meets the demands of your specific projects.

Best Practices for Effective Use of Needle Guns

Utilizing a needle gun effectively requires preparation and technique. This section offers guidelines to enhance your operational efficiency.

Preparation Steps Before Using a Needle Gun

Before firing up your needle gun, ensure that:

- You have cleared the work area of any unnecessary items.

- Materials to be treated are properly secured.

- You correctly select the needle set based on the type of metal and rust thickness.

- Proper ventilation is established if working indoors to mitigate hazardous dust exposure.

Techniques for Optimal Performance

To achieve the best results while using a needle gun, follow these methods:

- Angle of Attack: Maintain an angle of approximately 30 degrees to the surface for maximum efficiency.

- Speed Control: Vary your speed based on the thickness of the material being treated; slower speeds are generally better for thick layers.

- Continuous Movement: Keep the needle guns moving continuously to avoid excessive wear on one spot, which can cause damage to the substrate.

Common Mistakes to Avoid with Needle Guns

While they are easy to operate, common mistakes can lead to sub-par results:

- Using the Wrong Needles: Not matching needles to the surface material can lead to ineffective cleaning.

- Neglecting Maintenance: Failure to regularly check needle condition or to clean the gun can reduce performance.

- Skipping PPE: Ignoring personal protective equipment increases the risk of injury and exposure to harmful dust.

Maintenance Tips for Your Needle Gun

Routine maintenance extends the life of your needle gun and ensures optimal performance. Here are some key maintenance practices.

Regular Checks and Cleaning Methods

To keep your needle gun in top condition:

- Inspect needles regularly for wear or damage and replace as necessary.

- Cleansing the gun’s exterior with a cloth to remove dust and grime will keep the tool functioning properly.

- Lubricate moving parts as suggested by manufacturer guidelines to prevent premature wear.

Repairs and Replacement Parts for Needle Guns

Replacement parts should be sourced from reputable manufacturers to ensure compatibility and reliability:

- Most needle guns allow for easy needle replacements, but ensure you follow proper installation procedures.

- For pneumatic models, check air hoses and couplings regularly and replace if they show signs of wear or leakage.

How to Extend the Lifespan of Your Needle Gun

To maximize the effectiveness and longevity of your needle gun:

- Store it in a dry, clean space, preferably in a carrying case to avoid dust accumulation.

- Detach air lines and hoses when not in use to prevent damage over time.

- Keep a user log for regular maintenance checks and repairs.

Case Studies: Needle Gun Applications in Various Industries

Needle guns serve multiple industries, each with unique applications. Below are some real-world examples illustrating their utility.

Industrial Uses of Needle Guns in Manufacturing

In heavy manufacturing, needle guns are essential for:

- Surface preparation of metal components before painting or coating, ensuring a proper bond between the surface and new material.

- Decontaminating machinery parts to maintain efficiency by keeping equipment free of rust and build-up.

Needle Guns in Automotive and Metal Restoration

Automotive restoration experts heavily rely on needle guns for:

- Removing rust from classic car frames to restore them to their former glory without damaging the underlying metal.

- Cleaning welds and joints before repainting to achieve a flawless finish.

Feedback and Results from Professionals Using Needle Guns

Numerous professionals have shared positive feedback regarding needle guns:

“The efficiency of the needle gun has transformed our metal prepping process. It’s easy to use, and the results are consistently impressive,” states John, a shop owner specializing in restoration.

Such testimonials demonstrate the value needle guns bring to professionals across different sectors, making them a worthy investment for those in the trade.