The Basics of Needle Guns

What is a Needle Gun?

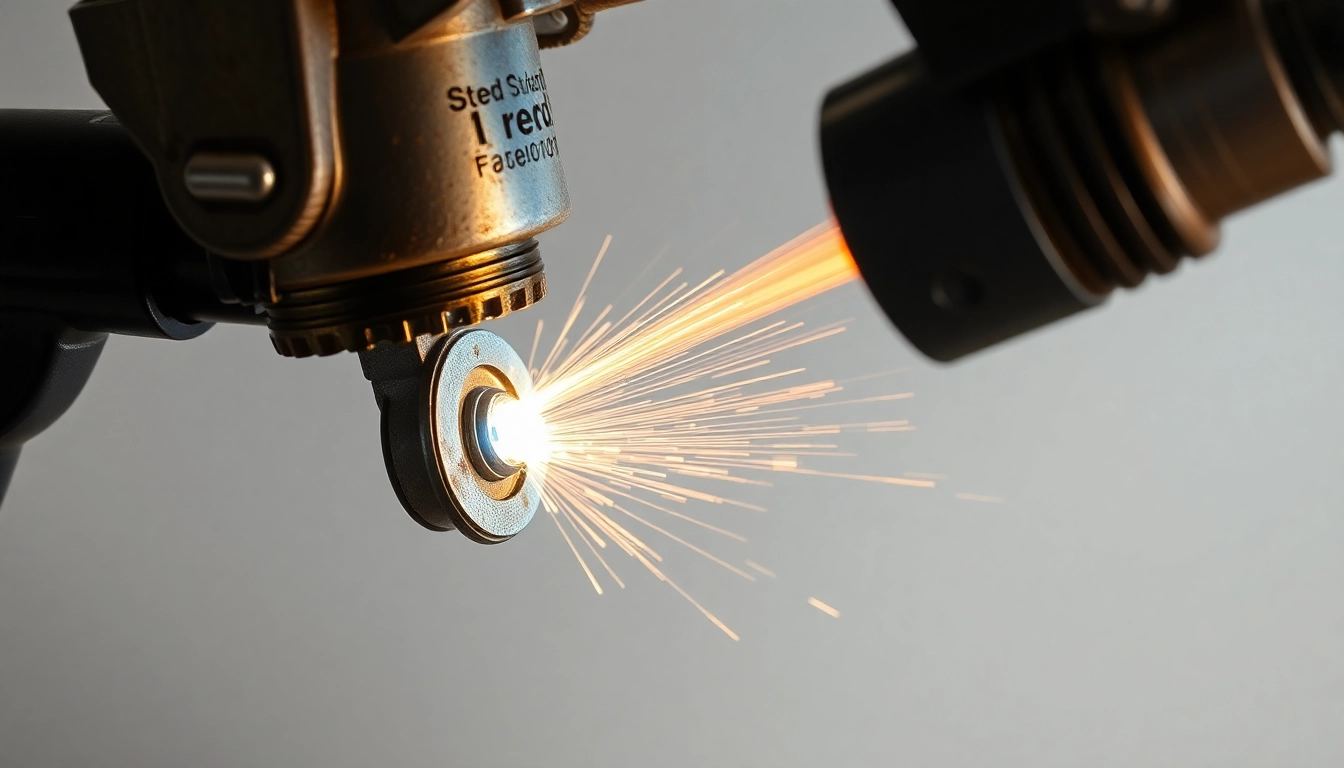

A needle gun, often referred to as a needle scaler or needlegun, is a tool specifically designed for surface preparation by removing rust, mill scale, and old paint from metal surfaces. Employing high-frequency vibrations, needle guns utilize multiple hardened steel needles that rapidly move back and forth to dislodge contaminants and surfaces from metalwork. Unlike manual scraping or sanding methods, a needle gun offers a quicker, more efficient way to achieve a clean finish, resulting in not only smoother surfaces but also aiding in longer-lasting paint adherence and corrosion protection.

How Needle Guns Work

At its core, the operation of a needle gun is straightforward yet effective. The tool is powered by either pneumatic (air-powered) or electric mechanisms. When activated, the needles vibrate at high speed, typically between 3,000 to 6,000 blows per minute. This hammering action breaks apart rust and paint, efficiently stripping surfaces.

Pneumatic needle guns work by using compressed air to power the oscillation of the needles, while electric needle guns rely on an electric motor. Both systems are engineered for durability and ease of use, allowing operators to effectively maneuver the tool during various applications.

Common Uses in Metalworking

Needle guns find diverse applications across many industries, with a focus on metalworking. They are particularly valued in:

- Automotive Repair: In auto shops, needle guns expedite the rust removal process on vehicles, ensuring that surfaces are ready for repainting.

- Shipbuilding and Repair: The marine industry often employs needle guns for maintenance and restoration of metal vessels, where saltwater conditions can lead to significant rusting.

- General Metal Fabrication: In manufacturing environments, needle guns play a critical role in surface preparation before applying finishes or coatings to metal products.

Types of Needle Guns

Pneumatic Needle Guns

Pneumatic needle guns are the most common type found in workshops. They are powered by compressed air from an air compressor. Given their high-frequency performance, they allow for efficient rust and paint removal without overcutting the surface beneath.

Advantages of pneumatic needle guns include:

- Higher rate of speed and efficiency for large surfaces.

- Durability in heavy-duty applications.

- Less likelihood of overheating compared to electric models.

Electric Needle Guns

Electric needle guns have gained popularity for their ease of use and portability. They operate on electricity rather than air pressure, making them ideal for smaller jobs or locations without compressed air supply.

Key benefits of electric needle guns include:

- No need for external air sources and hoses, allowing for easier handling.

- Potentially quieter operation compared to pneumatic tools.

- Compact design suitable for tight spaces.

Choosing the Right Type for Your Needs

Selecting the suitable needle gun depends on the specific needs of your project. Factors to consider include:

- Project Scale: Larger jobs may benefit more from pneumatic needle guns due to their speed and efficiency.

- Environment: If compressed air is not accessible, electric models would be a better fit.

- Maintenance Considerations: Pneumatic tools typically require more upkeep, while electric options may need less frequent servicing.

Advantages of Using a Needle Gun

Efficiency and Speed in Surface Preparation

One of the standout advantages of needle guns is their remarkable efficiency. Traditional methods of surface preparation, such as sanding or using chemical strippers, are often labor-intensive and time-consuming. In contrast, needle guns reduce the time taken to prepare surfaces, allowing workers to focus on other aspects of their projects.

The high-speed action allows operators to cover large areas rapidly, ensuring that jobs can be completed within deadlines and reducing labor costs in industrial settings.

Cost-Effectiveness Compared to Alternatives

The initial investment in a needle gun can be offset by its cost-effectiveness over time. Considering the savings in labor—shorter job completion times lead to reduced hours billed—many companies find that using a needle gun is financially beneficial.

Moreover, the longevity of a properly maintained needle gun surpasses that of many cheaper hand tools and equipment, further adding to its value proposition.

Reducing Manual Labor and Enhancing Ergonomics

With ergonomics becoming increasingly important in workplace safety, needle guns provide a solution to the strenuous manual labor associated with surface prep. The use of a power tool reduces the risk of fatigue and repetitive strain injuries, which are common in industries like automotive and metal fabrication.

Thus, workers can maintain productivity without excessive physical strain, resulting in a healthier work environment.

Common Applications for Needle Guns

Automotive Repair and Restoration

In automotive repair, needle guns are indispensable for preparing body panels and frames before reapplication of paint or protective coatings. They efficiently remove rust and paint without damaging the underlying metal, ensuring a surface that meets the standards for high-quality finishes.

Restoration experts rely on needle guns for vintage car refurbishment, where preserving the integrity of metal is crucial. Proper use of these tools can dramatically enhance the aesthetic and functional value of restored vehicles.

Marine and Shipboard Use

For marine applications, the effectiveness of a needle gun in removing rust and old paint is essential for maintaining the safety and efficiency of vessels. Ships often suffer from corrosion due to exposure to saltwater and other harsh elements.

Utilizing a needle gun during routine maintenance allows for effective surface preparation during inspections and repairs, significantly extending the life of maritime structures.

Industrial Maintenance and Renovation

In industrial settings, maintaining machinery and equipment is vital for operational efficiency. Needle guns help facilitate quick and thorough cleaning and preparation before painting or refinishing machinery, minimizing downtime.

This fast-paced environment benefits from the speed and efficiency of needle guns, allowing operators to continue production with minimal disruption.

Maintenance Tips for Your Needle Gun

Regular Cleaning Procedures

Maintaining your needle gun includes regular cleaning to preserve its effectiveness. After each use, it’s essential to wipe down the body of the tool and inspect the needles for any wear or damage. Accumulated debris can impair functionality, so using pressurized air to blow out needle areas is recommended.

Additionally, lubricating moving parts according to the manufacturer’s recommendations will help prolong the life of the tool and ensure consistent performance.

Adjusting Air Pressure and Usage Tips

If you operate a pneumatic needle gun, monitoring air pressure is critical. Proper air pressure maintains the optimal performance of the tool, typically ranging from 80 to 90 PSI. Adjustments should be made based on the conditions and surface type being worked on.

Operators should avoid applying excessive pressure during use, which can lead to premature wear on both the needles and the surface being prepared.

Identifying and Fixing Common Issues

Like any tool, needle guns can encounter issues that may affect performance. Common problems include lack of power, which may stem from insufficient air supply for pneumatic models, or electrical issues with electric variants.

Inconsistent needle movement can also indicate wear or breakage in the needle assembly. Regular checks and replacements are necessary to ensure optimal functioning.